Overview

Specifically designed for laboratories, small factories and individual makers

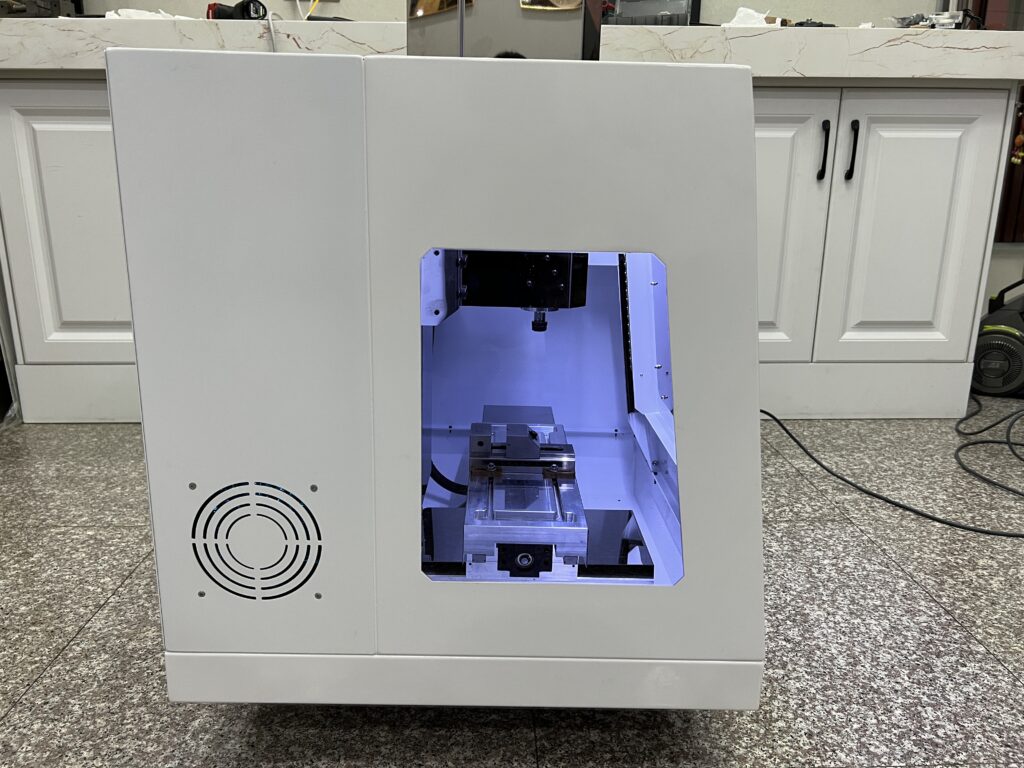

Integrated sheet metal shell protection, the movement shaft is protected by stainless steel, equipped with an air mist cooling device, and the bottom is designed to be waterproof.

Supports processing of various consumables, supports cutting and milling of plastic, wood, aluminum, copper, iron, gold, silver, steel and other materials.

Video

Feature

800w

800W water-cooled high-speed mold spindle,Sheet metal chassis, stainless steel protection, spray cooling processing available

1500rpm/min

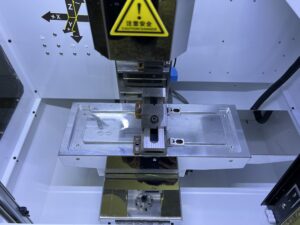

36V DC integrated servo,High control precision, smoother and more stable movement.T-slot M5 workbench

24000rpm

Its speed can reach up to 24000rpm,Cutting is easier.Automatic tool setting, C7 ball screw, Shangyin MGN15 linear guide.

Specs

| Mechanical | |||

| Package Size | W810×D660×H700mm | Package Weight | 100kg |

| Equipment Size | W700×D560×H620mm | Equipment Weight | 75kg(N.W) |

| Workbench Size | W370×D135mm | Workbench Max Load | 20kg |

| XYZ Effective Stroke | X170×Y135×Z180mm | *A-axis Effective Stroke | A:360° |

| Fixture Clamping length | 30mm | 4-axis Machining Range | Φ80×L130mmH120mm |

| Protection | Stainless Steel Dustproof | 800W 24000r/min | |

| 3-axis Machining Range | ≤0.02mm | 4-axis Machining Accuracy | ≤0.05mm |

| XYZ Ball Screw | 1204 C7 | A axis | 1:5 Reducer |

| XYZ Linear Guides | Hiwin MGN15 | Frame | 6061-T6 Aluminum |

| Processing Speed | 4000mm/min(Varies by Material) | Part Fixture | T-slot, M5 T-nut T-slot Spacing 80mm |

| Tool Diameter&Length | ER11 0-8mm,≤75mm | ||

| Processing Materials | Metal: Aluminum Alloy,Copper Alloy,Gold Alloy, Silver Alloy, *Steel, *Titanium Alloy | Non-Metal: Plastic, Wood, Wax, Jade, Glass, etc | |

| Electric | |||

| Drive Motor | 24V DC Integrated Servo 1500rpm/min | Spindle Motor | Φ62mm 800W 24000rpm Water-cooled Mold Spindle Can upgrade to 1500W |

| Drive Power | 220V Input 24V15A Output | Controller | DDCS V3.1 |

| Reset Switch | Photoelectric sensor | Tool Touch Sensor | Contact force 1.5N, Repeated Tool Setting Accuracy 2um |

| Software | |||

| Control Software | / | Tool Path Software | PowerMill, Fusion360,JDPaint,UGNX etc |