Desktop NC pro

Operation Video

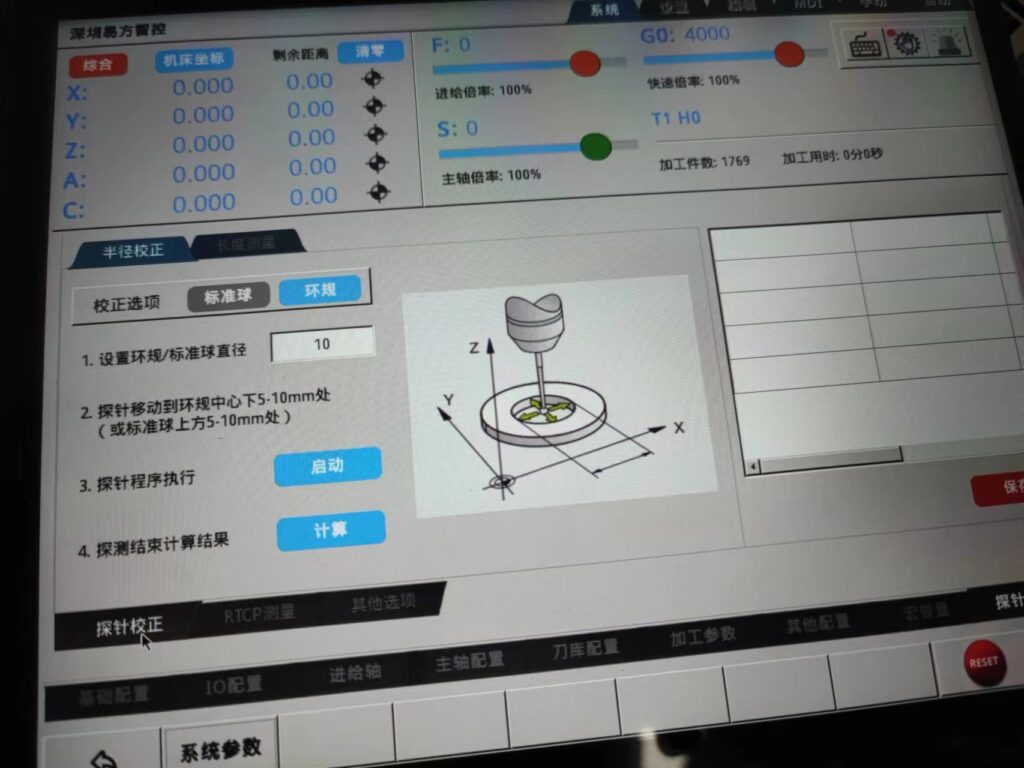

Probe Measurement

Automated Upgrade – Auto Door&Pneumatic clamp

Specs

| Machinery | ||||

| Packing Dimension | W870×D620×H1000mm | Packaging Weight | 160kg | |

| Equipment Dimension | W800×D550×H800mm | Equipment Weight | 145kg | |

| Workbench Dimension | Φ100mm | WorkbenchMax. Load | 5kg | |

| XYZ Effective Travel | X160×Y200×Z130mm | A&C Effective Travel | A:-30-120°,C:360° | |

| 3-Axis Machining Range | X160×Y200×Z125mm | 4-Axis Machining Range | Cylinder: Φ150×H105mm /Φ1000×H120mmCube: W125×D125×H110mm | |

| 3-Axis Machining Accuracy | Linear axis parallelism & perpendicularity 0.03mmSpatial accuracy<0.02mm | 4-Axis Machining Accuracy | Linear axis parallelism & perpendicularity 0.05mmSpatial accuracy<0.05mm | |

| XYZ Ball Screw | X&Z:1204 C5 Y:1604 C5 | A&C Axis | 1:80 20 Harmonic reducer return <1’1N servo motor torque after deceleration | |

| XYZ Linear Guideway | X&Z: Hiwin MGN12,Y:Hiwin MGN15 | Frame | Forced Parts: 45 # Quenched &Tempered SteelOthers:Al6061-T6 Aviation Aluminum | |

| Machining Speed | 4000mm / min (vary by material) | |||

| Principal Axis | Φ65mm Water-cooled Spindle | Protect | Accordion dustproof Oil seal waterproof & dustproof. | |

| Tool Diameter & Length | ER11 0-8mm,≤75mm | Part Fixtures | Steel fixture with reserved hole positionCan add er50 clip holder, 63,80 Chuck | |

| Work Material | Metal: aluminum alloy, copper alloy, gold alloy,silver alloy, * steel, * titanium alloy | Non-metal: plastic, wood, wax, jade, glass, etc | ||

| Electrical | ||||

| Drive Motor | A 36V DC Servo1500rpm/min | Spindle Motor | 800W, 24,000 rpmCan Upgrade 40000 rpm | |

| Drive Power | 220V Input,36V15A output | Control System | Windows | |

| Home Switch | Photoelectric Sensor | Tool Setter | Contact force 1.5N Repeatedtool setting accuracy 2um | |

| Software | ||||

| Control Software | e2 Studio | Program Software | PowerMill, Fusion360, NXUG,MasterCAM | |

Standard List

| No. | Type | Name | Description | PCS |

| 1 | Equipment | Machine | Bare machine, excluding sheet metal | 1 |

| 2 | Material Fixture | A-Type Self-Centering Vise | Clamps for 8-55mm square materials | 1 |

| 3 | Tool Holder | ER11 Collet | ER11-4 & ER11-6 | 2 |

| 4 | Tools | End Mills, Ball Mills | 0.2mm End Mills (for engraving) × 10, 2, 4, 6mm End Mills × 2, R-Ball Mills × 2 | 18 |

| 5 | Electrical | Power Box | Motor Control Inverter | 1 |

| 6 | Electrical | Power Cable | Equipment’s total power supply | 1 |

| 7 | Electrical | USB Data Cable | Connects the computer to the host | 1 |

| 8 | Electrical | Electronic Handwheel | Axis movement control | 1 |

| 9 | Tools | Hex Key Set | 1.5-10mm, 9PCS | 1 |

| 10 | Tools | Spindle Wrench Set | 14 & 17mm open-end wrenches | 2 |

| 11 | Material | Substitute Wood Blocks | For practice | 4 |

Warranty

- The warranty period is one year, and replacement parts are available at cost after the warranty expires.

- If natural damage occurs during the warranty period, we will provide parts and remote guidance free of charge.

- Warranty does not cover incorrect operation, unauthorized product disassembly, or deliberate human damage