2. Compare

2. Content

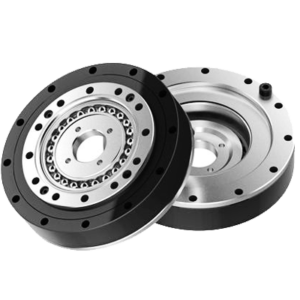

Harmonic reducer

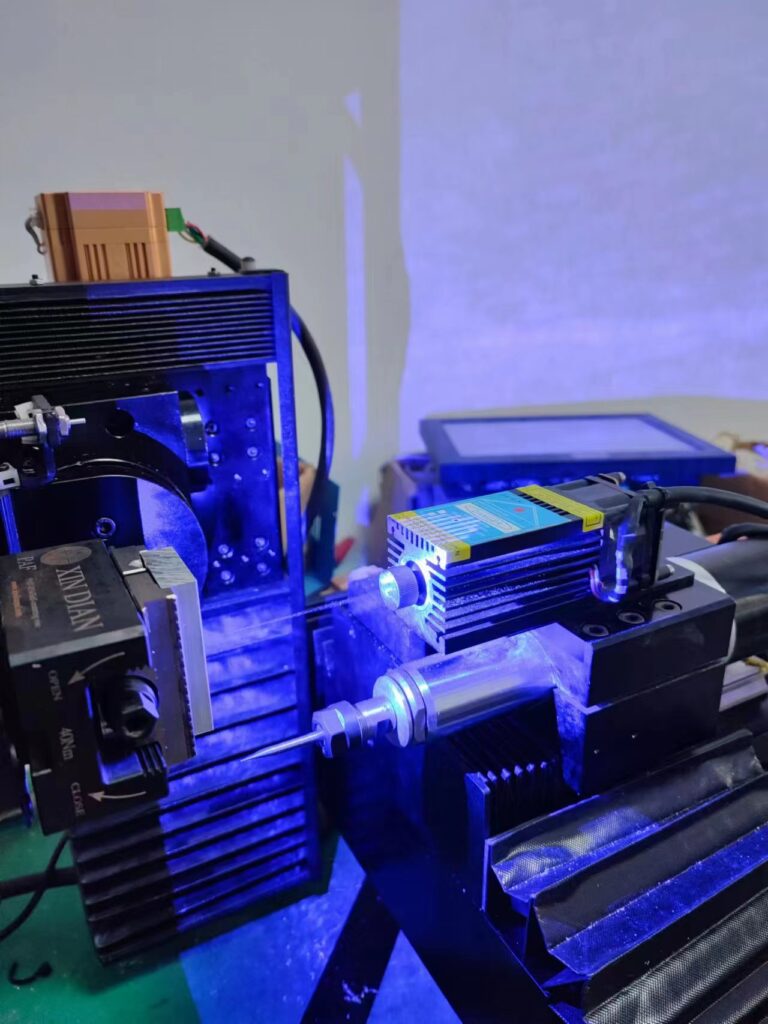

Water-cooled spindle

DC Servo motor

3. Specs

| Machinery | |||

| Packaging Dimension | W800×D600×H800mm | Packaging Weight | 120kg |

| Equipment Dimension | W600×D400×H510mm | Equipment Weight | 75kg |

| Workbench Dimension | Φ100mm | Workbench Max. Load | 5kg |

| XYZ Effective Travel | X160×Y200×Z130mm | A&C Effective Travel | A:-30-120° C:360° |

| 3-Axis Machining Range | X160×Y200×Z125mm | 4-Axis Machining Range | Cylinder: Φ150×H105mm/Φ100×H120mm, Cube: W125×D125×H110mm |

| 3-Axis Machining Accuracy | Linear axis parallelism & perpendicularity 0.03mm Spatial accuracy<0.02mm | 4-Axis Machining Accuracy | Linear axis parallelism & perpendicularity 0.05mm, Spatial accuracy<0.05mm |

| XYZ Ball Screw | X&Z:1204 C7 Y: 1604 C7, Can Upgrade C5 | A&C Axis | 1:80 20 Harmonic reducer return <1′ 1N servo motor torque after deceleration |

| XYZ Linear Guideway | X&Z:Hiwin MGN12, Y:Hiwin MGN15 | Frame | Forced Parts: 45 # Quenched&Tempered Steel Others:Al6061-T6 Aviation Aluminum |

| Machining Speed | 4000mm / min (vary by material) | Protect | Accordion Dustproof Oil Seal Waterproof &Dustproof |

| Principal Axis | Φ65mm Water-cooled Spindle | Part Fixtures | Steel fixture with reserved hole position Can add er50 clip holder, 63,80 card |

| Tool Diameter & Length | ER11 0-8mm,≤75mm | ||

| Work Material | Metal: aluminum alloy, copper alloy, gold alloy, silver alloy, * steel, * titanium alloy | Non-metal: plastic, wood, wax, jade, glass, etc | |

| Electrical | |||

| Drive Motor | A 36V DC Servo 1500rpm/min | Spindle Motor | 800W, 24,000 rpm Can Upgrade 40000 rpm |

| Drive Power | 220V Input 36V15A output | Control System | Windows |

| Drive Power | Home SwitchPhotoelectric Sensor | Tool Setter | Contact force 1.5N Repeated Tool setting accuracy 2um |

| Software | |||

| Control Software | DNC Studio | Program Software | PowerMill,SprutCAM,Fusion360 NXUG,MasterCAM etc |

4. Structure

5. Deliver List

| Standard Delivery List | |||||

| No. | Type | Name | Describe | PCS | Price/USD |

| 1 | Equipment | DesktopNC Turbo | with Enclosure &Industrial touch screen computer | 1 | $4,899 |

| 2 | Metal Clamps | A-type self-centering vise | Clamping range for square material: 8-55mm | 1 | |

| 3 | Tool Holders | ER11 collets | ER11-4 & ER11-6 | 2 | |

| 4 | Tool | End mills, flat mills, ball mills | 0.2mm flat mill x 10, 2mm, 4mm, 6mm end mills x 2, R1 ball end mill x 2 | 18 | |

| 5 | Electrical | Power supply box | Motor control frequency converter | 1 | |

| 6 | Power cord | Equipment power supply | 1 | ||

| 7 | USB data cable | Connection between computer and machine | 1 | ||

| 8 | Manual Pulse Generator | Manual operation of axis movement | 1 | ||

| 9 | Hand Tools | Hex wrenches | 1.5-10mm 9PCS | 1 | |

| 10 | Spindle wrenches | 14 & 17mm open-end wrenches | 2 | ||

| 11 | Materials | Wood substitute material | For practice use | 4 | |

| Optional Upgrade Accessories | |||||

| 1 | Transmission | Grinding ball screw | 1204 &1604 | 3 | $220 |

| 2 | Spindle | Price difference for upgrading to 40000 rpm spindle | Same 800W with a diameter of 65mm | 1 | $140 |

| 3 | Tool Holders | Spindle with ER11 collet chuck | 2.3.4.5.6.7.8mm collets | 7 | $25 |

| 4 | Square Materaial Clamps | Type-A Self-centering vise with reversible jaws | Clamping range of 50-75mm | 1 | $30 |

| 5 | Type-B Self-centering vise with enlarged jaws | Clamping range of 0-100mm | 1 | $140 | |

| 6 | Round Material Clamps | Hand-tightened 80mm chuck (4-jaw) | 48mm stroke height (can hold round and square material with 4-jaw chuck) | 1 | $60 |

| 7 | Mechanical 80mm chuck (3-jaw) | 66mm stroke height (better concentricity than 4-jaw chuck) | 1 | $65 | |

| 8 | ER40 collet chuck | High concentricity, compatible with ER40 collet chuck (can hold Φ4-30mm) | 1 | $40 | |

| 9 | ER40 collet chuck | 6.8.10.12.15.18.20.25.28.30mmollet chucks (corresponding to the same diameter of round material) | 10 | $65 | |

| 10 | ER50 collet chuck (Choose ER50 or ER40) | Compatible with ER50 collet chuck (can hold Φ4-36mm) | 1 | $40 | |

| 11 | Choose your own model for ER50 collet chuck | Choose your own size from 4-36mm, priced at $12 each. | 1 | $12 | |

6. Fixture

7. Case

8. Operation

Customized service

Special Tool Design

Special Fixture Design

Modified Chuck Design

We can develop special fixtures, special tools, laser and other chuck modification solutions for special processes based on demand and relying on strong research and development capabilities

+

Customer

Slutions

Engineer

YEARS

Solution

Metal Processing

Commonly used in processing copper alloy watch covers, motor covers and other aluminum alloy parts

Object Carving

Using the powerful surface processing function of five axes, it is used for the carving of human figures

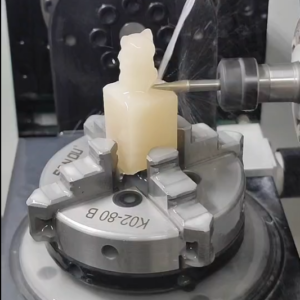

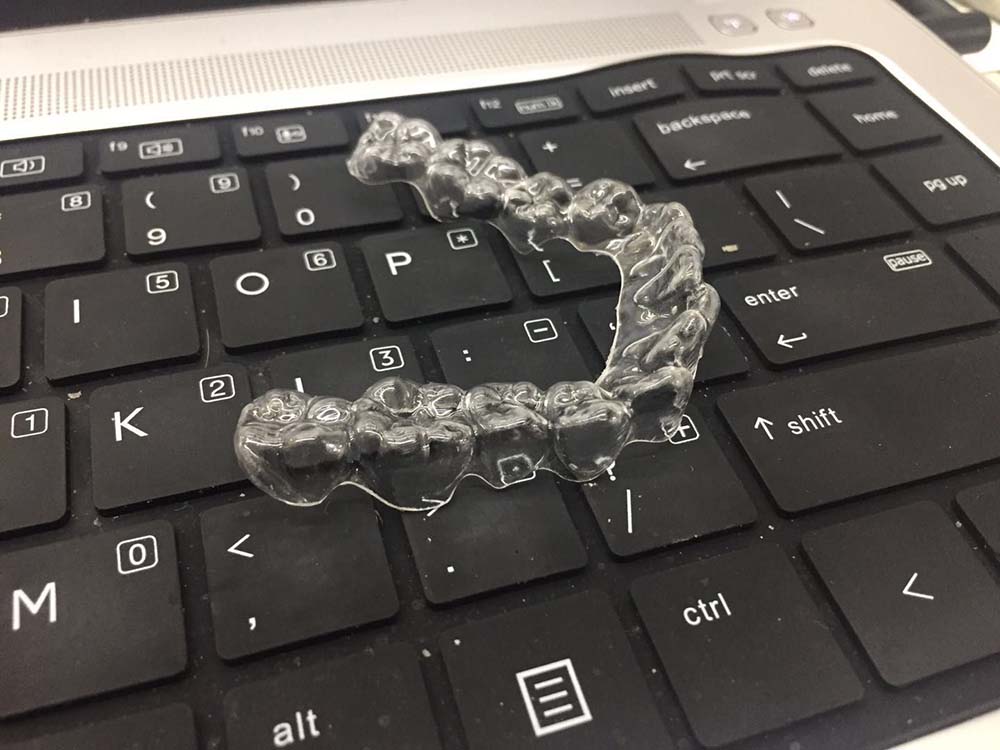

Dental

For the cutting of the outer edge of invisible braces and the processing of wax-type ceramic teeth

Our Company