Overview

Vedio

Features

Compact Design, Unlimited Possibilities

Injection molding machine heats thermoplastic or thermosetting plastics to a molten state, then injects them under high pressure into precise molds to rapidly form plastic products of various shapes and sizes.

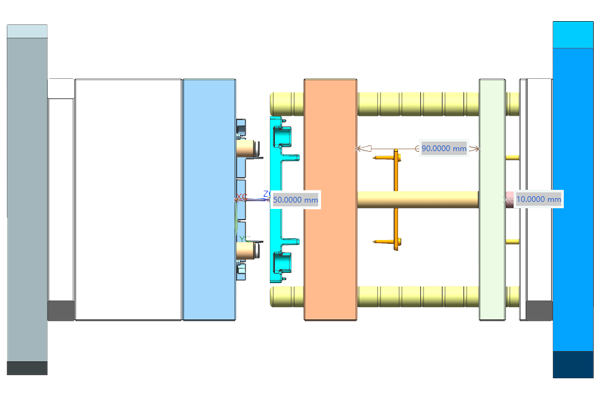

Sturcture

Specs

| Equip Dimensions | W230×D66×H90 cm | Equip Power | 3.5 kW |

| N.W | 160 kg | G.W | 290 kg |

| Packing Size | W160×H98×D48 cm | Clamping Force | 15 Tons |

| Motor | 1.5kW Servo Motor | Power Supply | 220 V/110 V |

| Screw Diameter | Φ16 mm | Max. Shot Weight(PS) | 35 g |

| Max. Mold Size | L184×W260 mm | Mold Thickness | 260 mm |

| Clamping Method | Toggle Mechanism | Molding Method | InHydraulic Plunger injection |

| Max. Injection Pressure | 120 Mpa | Max. Shot Speed | 150 cm³/s |

| Mold Opening Stroke | 110 mm | Max. Heat Temp | 400±1 ℃ |

| Ejector Stroke | 40 mm | Heating Stage | 3 |

| Lead time | Machine 20days,Mold 25days | Materials | PP PE ABS POM PA PC PLA TPE PMMA etc |

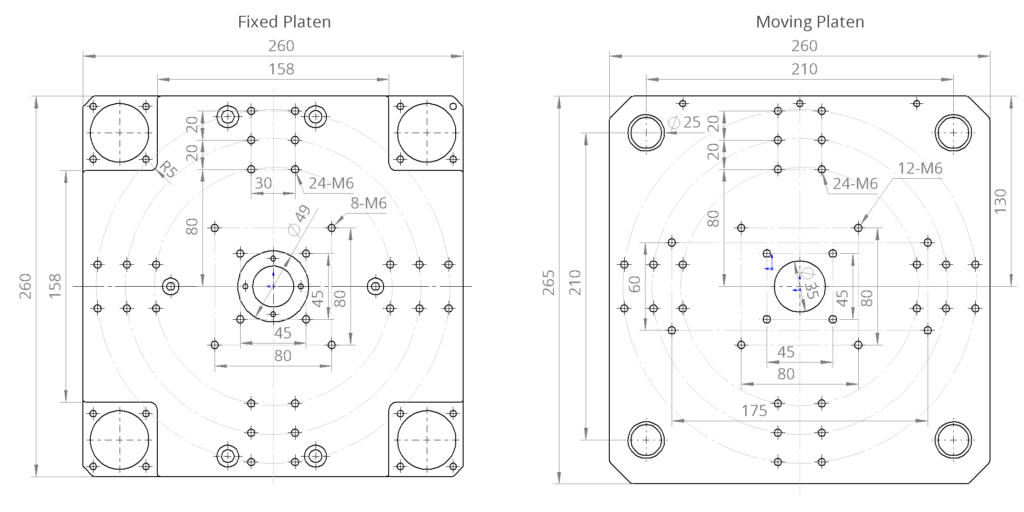

Mold

① Requirement Submission: Specify the product’s material, function, and production requirements, and submit the STEP file.

② Review and Design: Evaluate manufacturability, make necessary adjustments, and determine key elements such as mold type, structure, and gate location.

③ Detailed Design: Create assem1bly and part drawings, select materials, and provide STEP files for confirmation.

④ Flow Analysis (Optional): Simulate flow and cooling to optimize the design.

⑤ Mold Manufacturing: Fabricate and assemble the mold through CNC machining, EDM, grinding, etc.

⑥ Testing & Validation: Conduct trial runs, produce samples, and make adjustments as needed.

Warranty

- Warranty period is 12 months.

- During the warranty period, the manufacturer will send free accessories for non-human damage and provide remote guidance for replacement.

- Out of warranty, the manufacturer can provide spare parts at cost price, or provide spare parts purchase channels for you to purchase by yourself.