Overview

Vedio

Features

Super cost-effective

Injection molding machine is a molding equipment that heats and injects thermoplastic or thermosetting plastic into a mold to form plastic products of various shapes and sizes.

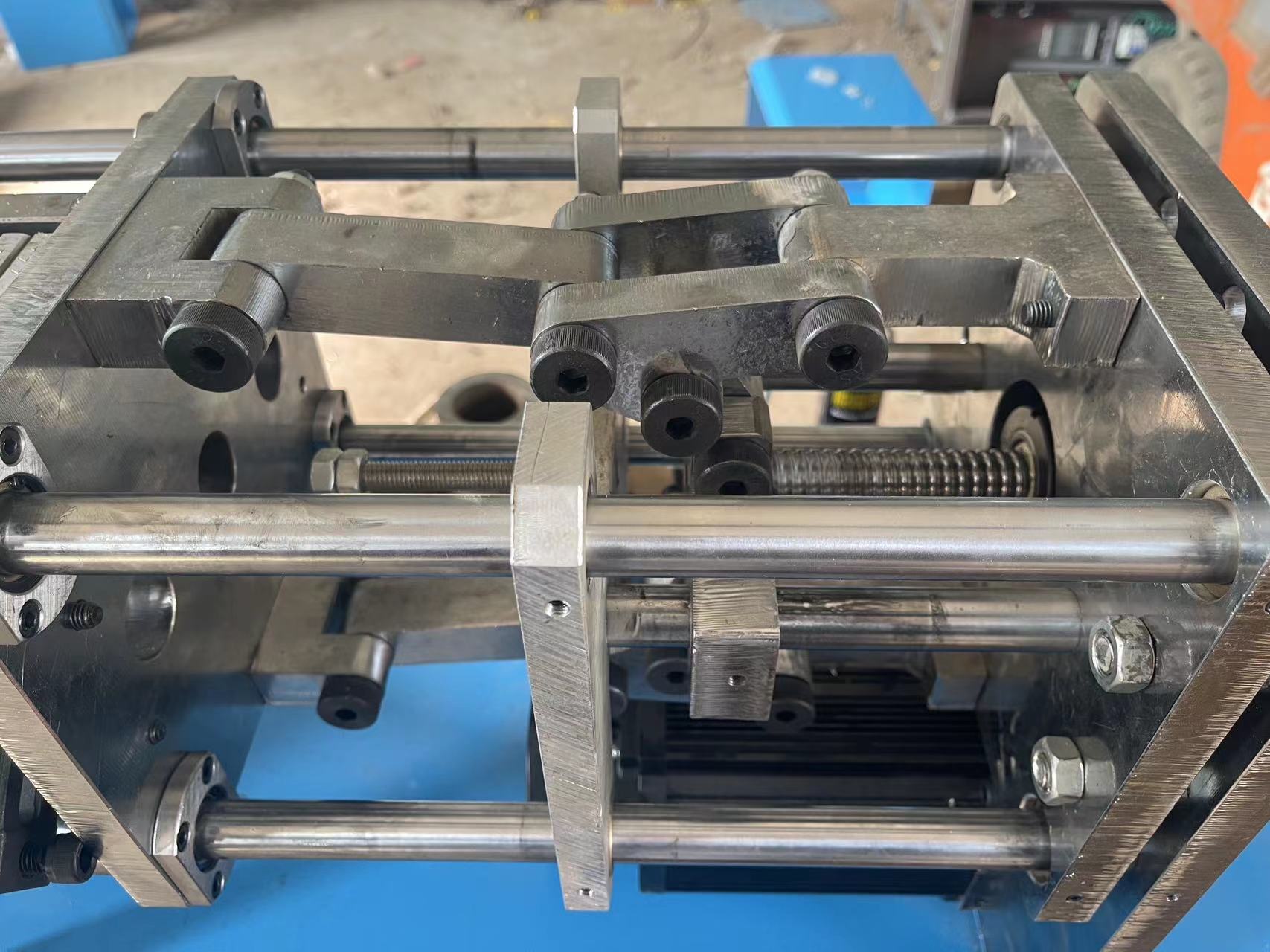

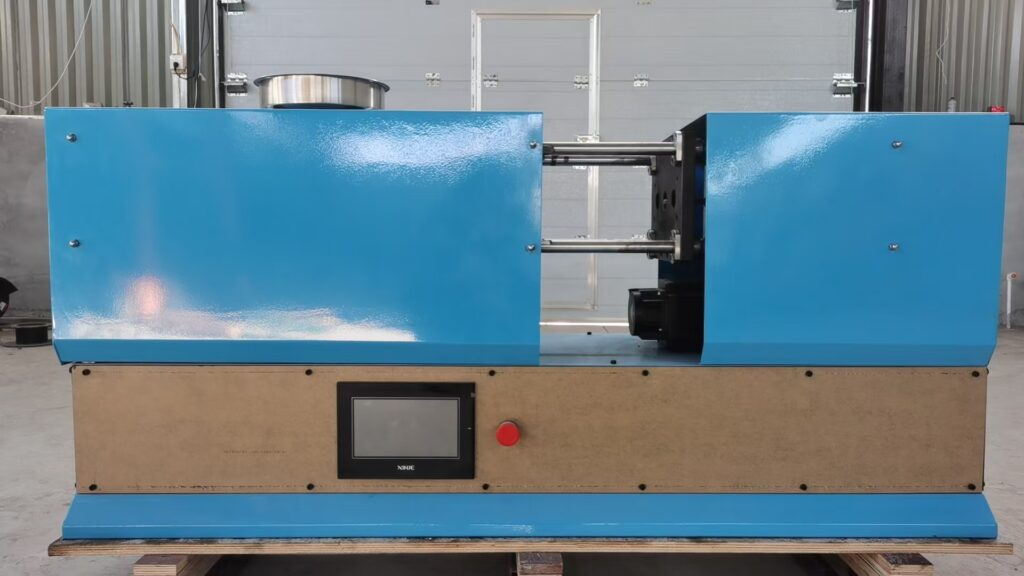

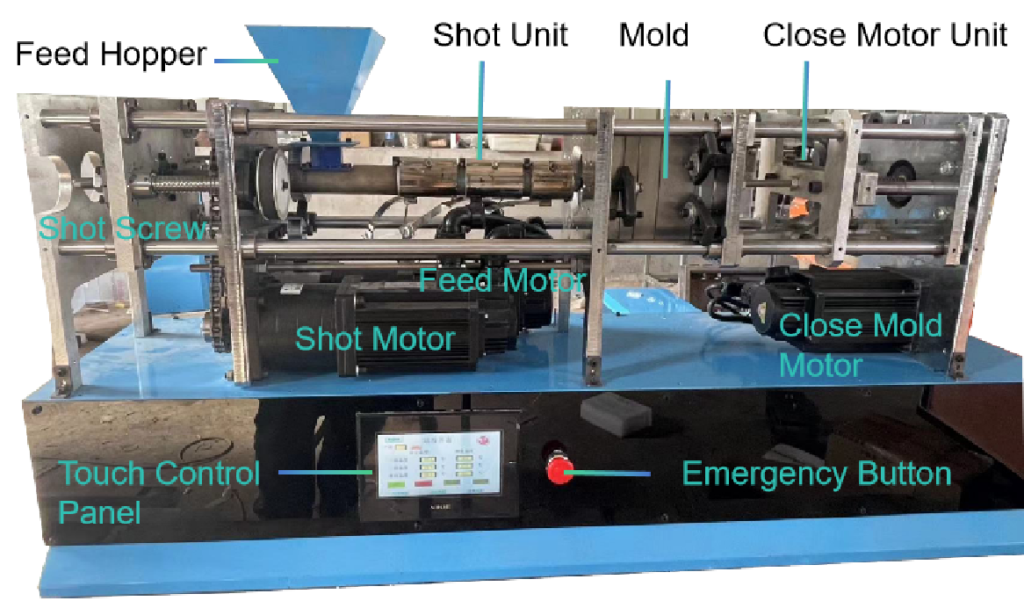

Sturcture

Specs

| Equipment | |||

| Packing Dimensions | W140×D65×H40 cm | G.W | 170 kg |

| Equip Dimensions | W145×D70×H45 cm | N.W | 160 kg |

| Equip Power | 3 kW | Screw Diameter | Φ16 mm |

| Max. Heat Temp | 400±1℃ | Heating Stage | 3 |

| Motor | 1.8 Kw Servo Motor | Power Supply | 220 V |

| Lead time | Equip 20 daysMold 25 days | Materials | PP PE POM PAPLA TPE PMMA etc |

| Products | |||

| Molding Method | Extrusion | Clamping Method | Ball Screw |

| Max. Shot Weight (PS) | 25 g | Clamping Force | 4 Tons |

| Max. Shot Speed | 120 cm2/s | Max. Injection Pressure | 100 Mpa |

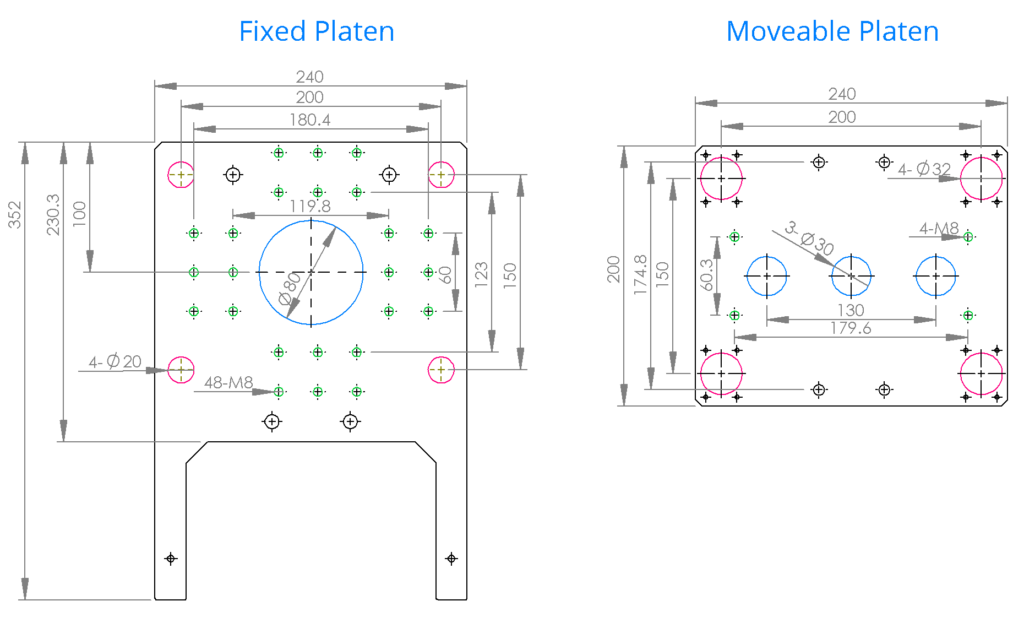

| Mold | |||

| Max. Mold Size | L200×D160 mm | Max. Mold Thickness | 200 mm |

| Mold Opening Stroke | 120 mm | Ejector Stroke | 15 mm |

Mold

Warranty

- Warranty period 12 months.

- During the warranty period, the manufacturer will send free accessories for non-human damage and provide remote guidance for replacement.

- Out of warranty, the manufacturer can provide spare parts at cost price, or provide spare parts purchase channels for you to purchase by yourself.